How to choose UHF RFID tags

2018-07-03 11:00:44

UHF RFID technology has been used in various industries due to its characteristics of long-distance reading and multi-tag reading.

Faced with a variety of different application requirements, RFID labels is various, with different performance, features, advantages, and disadvantages.

Some RFID tag models are specifically developed for specific application approaches and scenarios, and with special designs for the size, material, and performance. Some models, which are universally designed and applied, can be applied to a variety of scenarios. Dedicated and general-purpose products will produce certain differences and gaps in the performance of different scenarios.

How to choose the RFID tag that is suitable for your project application, in order to achieve the good operation of the entire RFID system and avoid the label link becoming theshort board of the RFID system?

Take UHF RFID tags as an example to illustrate the selection of RFID tags. We hope to provide reference documents and assistance for everyone!

First of all, it is necessary to clarify the environment in which the tags are applied.

Especially UHF RFID products, metals and liquids have a great influence on their performance. Therefore, the application of the environment is metal or non-metal, liquid orplastic, glass, wood, etc., is the primary consideration. This will directly determine the type of UHF RFID tag selection. Conventional labels cannot be used directly on metalsurfaces. Only specially designed anti-metal labels can provide good performance on metal surfaces, and the greater the performance of such labels is, the larger the metalsurface is. UHF RFID tag performance is easily affected by the environment. To determine whether the product is suitable for the actual application environment, it must have areference value for the performance that must be directly used for testing on the object in the early stage of testing.

Secondly, it is necessary to identify the desired value for the tag identification distance.

The reading distance is also directly related to the reader and the antenna. It is necessary to clarify the relationship between the tag and the mounting position and angle of the reader antenna. At the same time, parameters such as power selection, antenna gain, polarization, and radiation angle all fall into the category that needs to be considered.In the entire RFID system, each detail may affect the actual reading distance, and can finally reach the project requirements or not, even the feeder (the length of the cableconnecting the antenna and the reader) needs to be considered.

Again, it is necessary to have a clear understanding and reasonable understanding of the dimensions of the label.

In our past many project experiences, customers often want the label size to be small, which is both nice and easy to install. However, the size of the tag is precisely one ofthe main factors that determine the performance of the tag. In general, the larger the size is, the better the label performance can be designed, and the size is related to themedia environment where the label is located, the substrate of the label, and so on. At the same time, how the tag is sealed is directly related to the cost of the tag. Theseare the factors that must be taken into account when the customer operates the project.

In addition, there are other detailed considerations such as:

Does the label have environmental reliability requirements such as temperature and humidity resistance?

How much data capacity does tag need to write?

What is the maximum number of tags that need to be read at a time?

And many more……

Of course, in the actual tag selection work, there are more things to consider than the above points. Based on our extensive project experience in the past few years, we need to continuously communicate requirements and a large number of tests in order to verify the suitability of the selection.

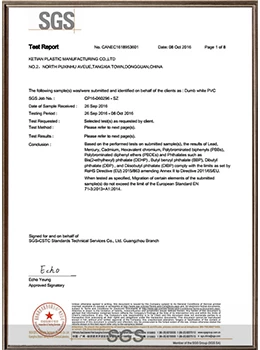

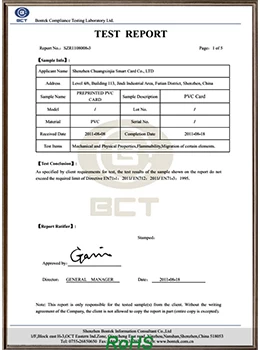

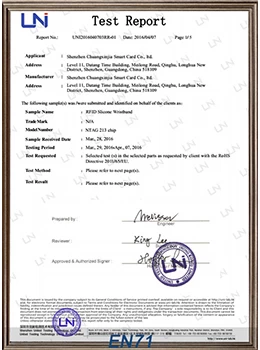

Chuangxinjia R&D team has passed the test of many large, medium and small projects in terms of testing and customization of UHF RFID products, RFID hardware products and RFID solutions, and has achieved satisfactory project results for customers. Welcome to contact for further information!

Faced with a variety of different application requirements, RFID labels is various, with different performance, features, advantages, and disadvantages.

Some RFID tag models are specifically developed for specific application approaches and scenarios, and with special designs for the size, material, and performance. Some models, which are universally designed and applied, can be applied to a variety of scenarios. Dedicated and general-purpose products will produce certain differences and gaps in the performance of different scenarios.

How to choose the RFID tag that is suitable for your project application, in order to achieve the good operation of the entire RFID system and avoid the label link becoming theshort board of the RFID system?

Take UHF RFID tags as an example to illustrate the selection of RFID tags. We hope to provide reference documents and assistance for everyone!

First of all, it is necessary to clarify the environment in which the tags are applied.

Especially UHF RFID products, metals and liquids have a great influence on their performance. Therefore, the application of the environment is metal or non-metal, liquid orplastic, glass, wood, etc., is the primary consideration. This will directly determine the type of UHF RFID tag selection. Conventional labels cannot be used directly on metalsurfaces. Only specially designed anti-metal labels can provide good performance on metal surfaces, and the greater the performance of such labels is, the larger the metalsurface is. UHF RFID tag performance is easily affected by the environment. To determine whether the product is suitable for the actual application environment, it must have areference value for the performance that must be directly used for testing on the object in the early stage of testing.

Secondly, it is necessary to identify the desired value for the tag identification distance.

The reading distance is also directly related to the reader and the antenna. It is necessary to clarify the relationship between the tag and the mounting position and angle of the reader antenna. At the same time, parameters such as power selection, antenna gain, polarization, and radiation angle all fall into the category that needs to be considered.In the entire RFID system, each detail may affect the actual reading distance, and can finally reach the project requirements or not, even the feeder (the length of the cableconnecting the antenna and the reader) needs to be considered.

Again, it is necessary to have a clear understanding and reasonable understanding of the dimensions of the label.

In our past many project experiences, customers often want the label size to be small, which is both nice and easy to install. However, the size of the tag is precisely one ofthe main factors that determine the performance of the tag. In general, the larger the size is, the better the label performance can be designed, and the size is related to themedia environment where the label is located, the substrate of the label, and so on. At the same time, how the tag is sealed is directly related to the cost of the tag. Theseare the factors that must be taken into account when the customer operates the project.

In addition, there are other detailed considerations such as:

Does the label have environmental reliability requirements such as temperature and humidity resistance?

How much data capacity does tag need to write?

What is the maximum number of tags that need to be read at a time?

And many more……

Of course, in the actual tag selection work, there are more things to consider than the above points. Based on our extensive project experience in the past few years, we need to continuously communicate requirements and a large number of tests in order to verify the suitability of the selection.

Chuangxinjia R&D team has passed the test of many large, medium and small projects in terms of testing and customization of UHF RFID products, RFID hardware products and RFID solutions, and has achieved satisfactory project results for customers. Welcome to contact for further information!